Screw Conveyor - Auger Flight- Screw Sectional Flight - Auger Conveyor - Sectional Flight - Auger Screw Conveyor - Screw Auger - Flight Sectional - Screw Feeder - Sectional Flight Auger - Hardfacing Screw Conveyor - Helix Flight - Sectional Flight Forming - Custom Helix Flight - Helical Flight - Helicoid Flight - Screw Conveyor Flight - Shafted Screw Conveyor - Mixer Powder Machine - Flighting - Screw Conveyor Parts - Auger Conveyor - Shaftless Screw -Conveyor Screw - Spiral Pipe - Spiral Tube - Conveyor Screw - Screw Conveyor Auger - Screw Flights - Auger Screw - Conveyor Screw - Screw Dosing - Shaftless Screw Conveyor - Screw Coveyor Auger - Screw Mixer Machine - Screw Conveyors - Auger Screw - Helicoid Flight - Ribbon Flight - Shaftless Flight - Conveyors Screw - Auger Flighting - Mixing Screw - Screw Conveyor Supplier - Screw Conveyor Manufacting - Screw Conveyor Manufacturer - Screw Conveyor Systems - Helicoid Screw Manufacturer - Centerless Screw - Screw Conveyor Manufacturers - Screw Flight Manufacturers - Heat Transfer Screw Processors -Screw Conveyor Heat Exchangers

Paddle rotor

Paddle rotor is an appropriated to remove or mix similar products with equal density and size. Paddles collet the product with less shearing stress than a ribbon rotor. Therefore, paddle mixers are a good solution for mixing friable materials. Working capacity can vary from 20% to 100% of the total mixer volume.

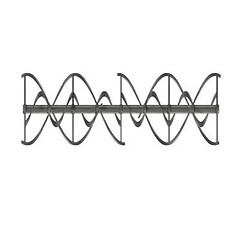

Double ribbon rotor

Double ribbon mixer produces a homogeneous mixture. The rotor is manufactured with external and internal helical ribbons that move the product in opposite directions, making a uniform backflow through all the machine. Ribbons can be arranged for central outlet. Mixing times vary from 5 to 20 minutes for working levels of 50% to 100%.

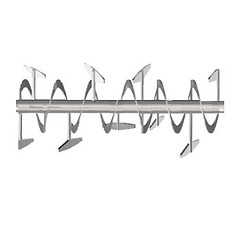

Combined rotor

Ribbon-paddle mixer consists on an internal ribbon and external paddles. This design is suitable for delicate materials. This type works similarly to the ribbon type but, external paddles produce less thermal energy and friction than the ribbon, so that it is an appropriate machine to mix heat sensitive materials.

Horizontal Paddle & Ribbon Mixers for powder and granulates

Horizontal Mixers (Paddles & Ribbon)

At Bega Screw Conveyor we offer our horizontal mixer manufacturing services for different materials, hard-to-handle powders, granular materials, as well as the appropriate advice to select the ideal type of mixer for the materials that require implementing and obtaining homogeneous mixtures in short periods of time. time, making an excellent balance between the power required and ton of mix.

The industries that we cover and to which we offer our Horizontal Mixers are: Food, Chemical, Agricultural and Pharmaceutical.

Depending on the material to be mixed, homogeneity required, mixing speed, different types of horizontal mixers are recommended, at Bega Screw Conveyor we offer 3 types of horizontal mixers:

a).- Ribbon Mixer / Ribbon Blender / Screw Ribbon Mixer

b).- Paddle Mixer

c).- Combined Mixer (Paddle and Ribbon)

The horizontal mixer is a standardized design and is an economical option for most mixing applications, in its 3 modes that we manufacture, it offers the same body configuration, which is a channel in a "U" shape with walls or covers to the ends fully welded. The agitator consists of a single horizontal axis, it can be with internal and external screw ribbons, paddles or a combination of both systems, any of these rotors / agitators has the function of mixing the products by directing the ends to the center of the mixer, where they are find manual or pneumatic unloading.

Horizontal Mixer Design & construction

The mixing capacity is approximately 70 to 80% of the total volume of the container, which provides:

1) Large capacity for material flow on the upstream side of the agitator.

2) Complete contact of the agitator with the batch materials.

3) Adequate distance from an optional spray manifold to introduce liquid additions to the downstream side of the agitator, resulting in even distribution.

The horizontal mixers are welded and one-piece construction, along with heavy gauge walls and fully reinforced end panels, make these vessels extremely rigid, allowing for exceptionally close tolerances between the agitator and the vessel wall. This, in turn, minimizes residual product in the channel after discharge, reducing material waste and cleaning time.

Materials of manufacture of Horizontal Mixers

Bega horizontal mixers are available in a variety of materials of construction, including:

a) .- Horizontal Mixer made of carbon steel.

b) .- Horizontal Mixer made of 304 / 304L and 316 / 316L stainless steel.

c) .- Horizontal Mixer made of abrasion resistant steel (AR-200/235)

The interior finishes of the horizontal mixers range from a standard clean factory finish to ultra high sanitary finishes, including 2B, # 4 and # 7 pharmaceutical mirror finishes to USDA sanitary finishes. Interior weld polishes range from standard 80 grit clean welds to 240 grit polished and radius welds.

Container standard features

-

Capacities from 1 to 1500 cubic feet

-

Lip or gland type seals.

-

Manual gate dump valve.

-

Fully welded and polished interior contact points

-

Heavy Duty Bearings

-

Hinged covers

-

Removable safety grilles

-

Chain and sprocket transmission (Direct Drive OPTIONAL)

-

Manufactured in carbon steel, SS-304, SS-316. Sanitary finish option.

Container Design Options

-

Custom covers.

-

Screw Conveyor discharge by dispenser.

-

Unloading with a valved bag packaging machine.

-

Temperature probes.

-

Spray Bar.

-

CIP systems.

-

Jackets Ball valve or bottom plug valves.

-

Load cells. Explosion proof motors.

-

Direct drive or shaft mounted systems.

-

Electronic control.

-

Soft start or VF units.

-

Ladder and walker.

Standard Horizontal Mixer Models

Types of Horizontal Mixers

Ribbon Mixer / Ribbon Screw Mixer / Screw Blender

The ribbon mixer is necessary in mixing processes with high demands for uniformity in materials such as powders, doughs, grains, detergents, pigments and more for the manufacture of a wide variety of products such as animal and pet food, pharmaceuticals and chemicals.

The ribbon mixer is mainly designed to mix dry and dry, or dry and liquid materials, especially for the ointments or high viscosity materials, for example, ceramic powders, stone paints, metal powders, etc.

The industries that most use these horizontal ribbon mixers (Screw Mixers) are food and beverages -such as cookies, pastries, spices, sugar pastes, bakery mixes, powdered milk-, cosmetics and daily care -such as creams, soaps, liquid and powder detergents-, chemicals - adhesives, ceramics, coatings, disinfectants, fiberglass, lime and cement, PVC pastes, rubber solutions, sealants, dyes and intermediates, fertilizers.

The Ribbon Screw mixers are suitable for mixing high viscosity materials, and it is widely applicable in paint, putty, mortar, pesticide, plastic gel, non-crushed food -whole grains- industries and more. It is also ideal for the intimate mixing of dry solids, coarse powders and granules.

The mixing time depends on the viscosity of the materials, the specific gravity, the degree of the powders and other situational factors such as humidity, explosiveness, temperature, etc., but an average of 15 to 25 minutes of effective mixing can be estimated.

Bega® Ribbon Mixer feature stationary U-shaped vessels with flat top sections and a dump valve on the bottom, and a single horizontally oriented shaft that rotates on external bearings, with radial arms that support the belt, the trowel or the plow as agitator elements, each of which offers different benefits in a wide range of applications.

These horizontal mixers force the material with the agitators or rotors, which accelerates the dispersion of individual particles. As a result, they can mix solids with solids as well as solids with low or high percentages of liquids to produce smooth pastes or slurries.

We manufacture from sanitary mixers for pharmaceutical and food products in a laboratory, pilot plant or production scale, to robust and high resistance machines for the recovery of soils, construction materials and oil sludge treatment, Bega custom designs each ribbon mixer , trowel and combination tape to provide maximum performance for your specific application.

Ribbon agitators are equipped with radial arms that support sections of ribbon-shaped stirrer blades mounted in a semi-helical arrangement. The blades that extend to the wall of the container tilt to move the material in one direction, while the inner blades tilt to move the material in the opposite direction. Developed by Bega, this split tape design mixes more quickly and completely than continuous tape elements. It also provides a greater surface area than trowel or plow elements, while mixing a wider range of free-flowing materials, including low-viscosity grouts, typically in 5 to 10 minutes, making it the most effective element. popular for horizontal mixer applications.

Bega's horizontal Ribbon Mixer for powders and granules video

Paddle Mixer

The paddle mixer is ideal for mixing pasty and lumpy products; the action of the paddles consists of the "tapping" of the product until the lumps disintegrate, achieving a uniform mixture. There are different types of "palettes" depending on the product to be mixed; Likewise, one or more deagglomerators (choppers) can be adapted to facilitate the breaking of lumps.

The paddle stirrer or mixer is best suited for stirring or mixing ingredients of equal size and density. The paddles are arranged to lift or collect the product producing much less shear than a belt type agitator. This makes the paddle mixer an ideal choice for friable materials. Fill levels can vary from 20% to 70% of the mixer working capacity.

Our horizontal paddle mixers mechanically fluidize the product and eliminate segregation caused by gravity, when ingredients with widely varying densities and granulometries are mixed. Mechanical fluidization is achieved through a combination of lifting the particles by a defined geometry that is achieved through the position and shape of the blades and a multi-zone rotor that rotates about 60% faster than traditional mixers.

Using helical paddle mixers achieves incredibly low coefficients of variability (Cv) in much shorter mixing times for most powdered or granular ingredients.

It is used in the preparation of treatment fluids or slurries that agitates the contents to achieve a well dispersed mixture. Paddle mixers are generally equipped with rotating blades that generate turbulence to mix the fluids and an action that prevents settling of solids prior to pumping.

Paddle mixers consist of shafts with radial arms that support numerous short paddles, which move material in smaller areas over shorter distances with greater cutting action than helical belt mixers, preventing the entire batch from rotating on its axis. While this increases cycle times, paddle agitators can handle materials that entangle, flow poorly, or tend to "roll" when using ribbon agitators. Additionally, paddle agitators can handle certain high viscosity abrasive materials and slurries more effectively than belt agitators. Replaceable hardened steel wear plates can be bolted to blade faces to increase abrasion resistance.